Uitgelichte klant

Onze klanten zijn de sleutel tot ons succes!

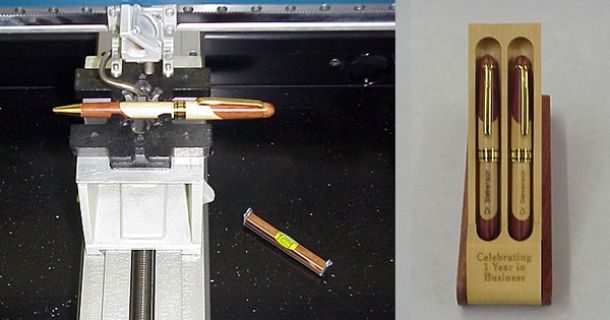

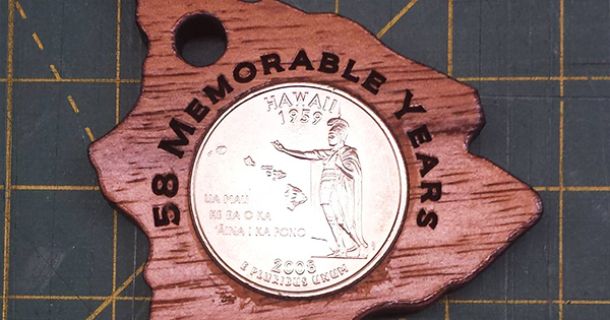

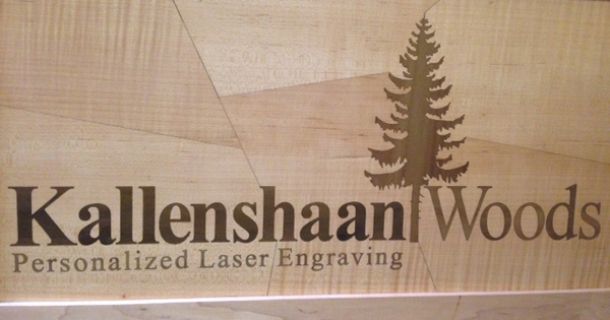

Onze trouwe en innovatieve klanten zijn een groot deel van wat Epilog Laser zo succesvol maakt. We horen altijd van klanten die onze lasersystemen op unieke en creatieve manieren gebruiken. Hieronder vindt u een reeks klantspotjes en succesverhalen die beschrijven hoe sommige van onze klanten hun lasersystemen gebruiken en hoe ze hun eigen bloeiende bedrijf creëren en onderhouden. We horen graag hoe onze klanten de lasersystemen van Epilog gebruiken.

Denk je dat je zelf een verhaal hebt dat je wilt delen?